Benefits of brazed heat exchangers – better heat transfer

One of the largest potentials to increase efficiency of heat exchangers lies within the heat-transfers: reducing condensing temperatures by 3 °K will improve overall system efficiency by approx. 10 % for a standard R 410 A air conditioning cycle. A minimization of the temperature difference between the air flows and the phase change temperatures of the refrigerants can be achieved by improving the heat transfer efficiency of the heat exchangers. Brazed microchannel heat exchangers have already proven that they are a cost effective solution for the utilization of this optimization potential – as well as boasting a number of other benefits (see below). Brazed microchannel heat exchangers have been the technology of choice in the automotive industry for the past 10 to 15 years, and are already making inroads into the stationary HVAC&R industry for the following convincing reasons.

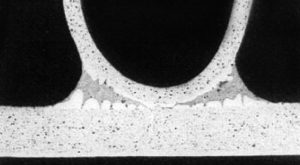

Poor contacts between fins and tubes account for approximately 5 – 10 % of heat transfer resistance in a standard heat exchanger manufactured by mechanical or hydraulic expansion of the round tubes because this always leaves imperfect connections between the parts. The microscopic image shows the small gaps between fins and tubes responsible for contact resistance that reduces heat transfer performance.

Fig. 1: Small gaps between fins and tubes reduce heat transfer performance in mechanically or hydraulically manufactured heat exchangers.

Brazed connections are much better because they metallurgically bond the fins and tubes in a single conductive material, eliminating all potential sources of contact resistance.

Fig. 2 Excellant heat transfer performance because no gaps in brazed connections.

What is the main reason that is stopping stationary HVAC&R industry and Home Refrigerators/AC manufacturers from using Nocolok Brazed Heat exchangers as brazed connection’s thermal efficiency of Nocolok Brazed Heat exchangers is much greater than that of mechanically/Hydraulically manufactured one.

Well – this question is not so easy to answer – and I can only point out some aspects reflecting my personal opinion. The capital investment required for a controlled atmosphere brazing line is a hurdle that only a few companies are willing to take. A change from mechanically assembled heat exchangers to all aluminium brazed heat exchangers involves completely new design concepts and know-how – the required learning processes are much slower than we would hope for. Furthermore, there seems to be a big concern about the corrosion performance of brazed HVAC&R units. This topic has been very successfully resolved by the aluminium producers – and there are a lot of material combinations available with excellent durability and corrosion resistance. Many companies seem to wait for future developments – i.e. they closely observe, if their competitors already offering NOCOLOK® brazed aluminium heat exchangers will succeed in the market – and they will only follow when there is no risk involved any more.