How to measure?

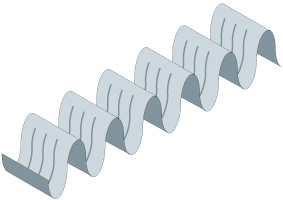

In the case of heat exchangers, the surface area being fluxed must first be determined. For ease of calculation, the louvers on the fin can be ignored. The radius on the fin can also be ignored.

Imagine then the fin pulled out of the heat exchanger and straightened out to form one long strip. Similarly, the surface area of the slots in the header can also be ignored.

Remember that in calculating the surface area of the heat exchanger, there are 2 sides to every tube, 2 sides to every fin and 2 sides to the headers. The total surface area is then expressed in m2: All dimensions are in meters (m) to yield a surface area in square meters.

Header

Assuming it is a cylindrical (condenser) header:

SA (m2) = (2 x 3.14 x radius of header(m)) x length of header (m) x 2 headers

Assuming it is a radiator header:

SA (m2) = length of header (m) x width of header (m) x 2 (sides/header) x 2 (headers)

Tubes

SA(m2) = width of tube(m) x length of tube (m) x 2 (sides/tube) x total number of tubes

Fins

Ignore the louvers in the fins

SA (m2) = width of fin (m) x (fin height (m) x number of fin legs/tube) x 2 ( sides/fin) x total number of fins

Total Surface area in m2 = SA headers + SA tubes + SA fins

To determine the flux loading, a degreased and thoroughly dry heat exchanger is weighed. The heat exchanger is then run through the fluxer, blow-off and dry-off section of the furnace. The heat exchanger is removed just prior to entering the brazing furnace and weighed again.

The flux coating weight is then determined using the following formula:

Weight of unit fluxed and dried (g) – weight of unit un-fluxed (g) x Surface area (m2)

To make sure that the flux loading was determined on a completely dry unit, run it through the dry-off section a second time and re-weigh.

See also: Flux loading