Benefits of brazed heat exchangers – pressure drop reduction

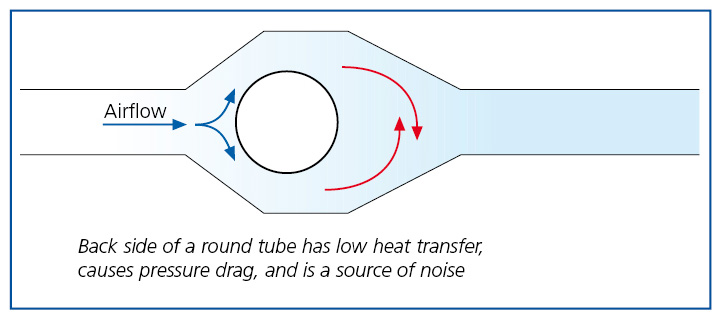

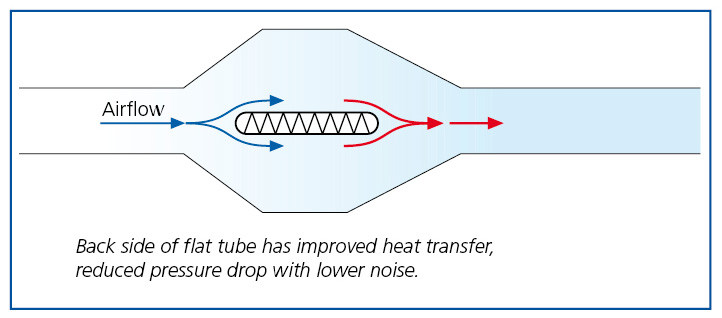

Brazing also offers the chance to change the design of heat exchangers by substituting round tubes with flat channels (microchannels) which offer improved heat transfer on both refrigerant and air sides for two reasons: better section/surface ratios, which affect the efficiency of heat exchange on the air and the refrigerant side; smaller surfaces in the air stream shadow where heat transfer is inefficient and lots of noise is generated. Brazed connections between fins and tubes are also rigid structures producing less mechanical noise in the presence of air turbulence.

More efficient heat exchange means lower air flows to exchange the desired heat, and microchannel technology already offers lower resistance to the air flow – flat is therefore better than round: reducing resistance by up to a factor of 3 under typical operating conditions (see figures below)!

cool stuff, cheers man