Flame Brazing Technology – Part 1

Aluminium joining – Brazing ‐ Flux function

What is brazing?

Brazing is the joining of metals using a molten filler metal. On melting, the filler metal spreads between the closely fitted surfaces, forms a fillet around the joint and on cooling forms a metallurgical bond. By technical definition ‚brazing‘ is a joining process in which the filler metal melting temperature is above 450°C, but below the melting point of the metals to be joined.

Aluminium brazing ‐ How does it work?

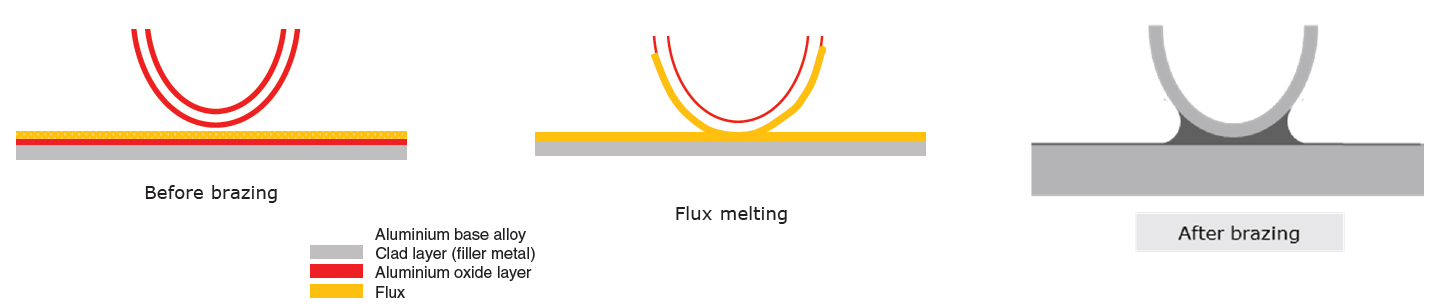

An aluminium oxide layer is formed instantly on aluminium in the presence of oxygen. This oxide layer has to be removed before brazing and the formation of a new oxide layer has to be prevented. The oxide layer is chemically dissolved by a FLUX.

Aluminium joining – Flame Brazing

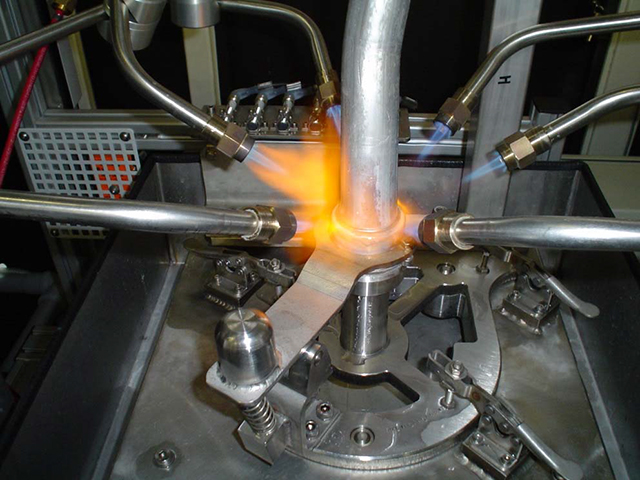

Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. (Gas mixture is preferred as it is cheaper and more comfortable).

Care must be taken to ensure even heat distribution. As with other aluminium brazing processes, close temperature control is important – it`must be closely monitored as there is no colour change in the aluminium to indicate temperature.

Aluminium joining – Basic Requirements

CORRECT FLUX / CORRECT FILLER METAL / CORRECT DIFFUSION OF FILLER METAL

The first requirement of an Aluminium brazing is to be chemically effective.

Fluxes are categorized as active (corrosive) and inert (noncorrosive)

CORRECT BRAZING TEMPERATURE

Between liquidus and solidus of filler metal

Decide how to manage the small thermal window between the melting temperature of the brazing filler metal and thermal damage to the base metals

BRAZING THROUGH CAPILARITY / RIGHT GAP OF THE BRAZING JOINT

Apart from the selection of flux and filler metal, important process parameters are the cleanliness and proper geometrical alignment of the individual components.

To be continued…

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!