Flux Characteristics and Transfer Systems in Electrostatic Application – Part 3

Flux Powder Fluidization:

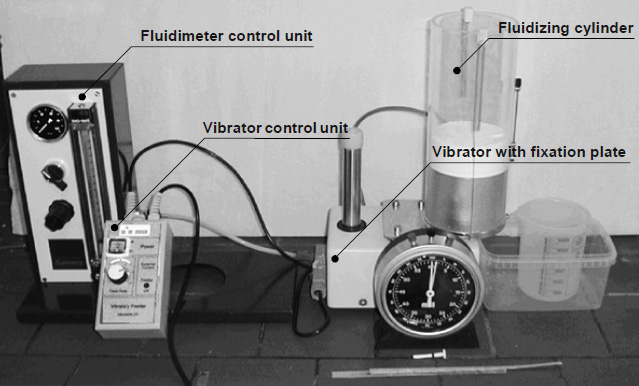

In an effort to develop a flux with more desirable properties for electrostatic application, the first step is to qualify criteria. In summary of the above, it is apparent that fluidization is one of them. There is standard equipment available on the market to quantify fluidization characteristics. However, when we tested these fluidity indicators, we found the fluidization ability of flux powder to be so poor that the results were meaningless unless a vibration unit was attached to the equipment. A photo of the modified installation can be found in the attachments. We combined a Binks-Sames powder fluidity indicator (AS 100 – 451 195) with a Fritsch vibration unit (L-24). The equipment consists of a fluidizing cylinder with a porous membrane on the bottom. The cylinder is mounted to a vibrator with a fixation plate. After the sample material (250 g) is placed in the cylinder, the vibration is turned on (via the vibrator control unit) and a consistent flow of dry nitrogen (via the fluidity meter control unit) is forced through the porous membrane. Depending on its potential to fluidize, the powder will start to expand until an equilibrium is reached (one minute). Measurements of the original and the fluidized height are taken at different points (see attachment).

Powder Fluidity Indicator

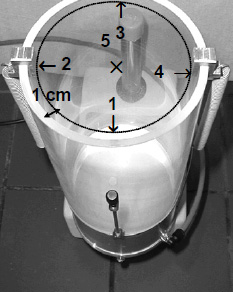

Indication of the locations for

the measure of the height of the

powder in both fluidized and

non fluidized condition.

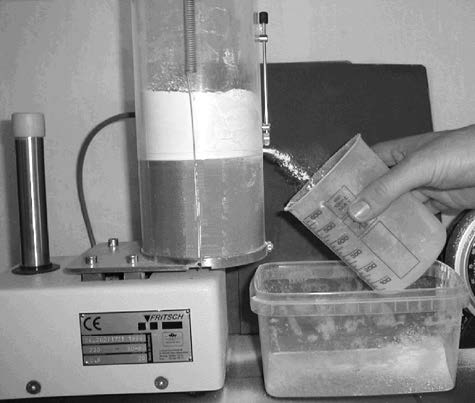

Collecting powder as it comes out of the

calibrated hole.

The second parameter determined with this device is the weight of powder flowing through a small hole on the side of the cylinder (as can be seen on the picture). Similar to the above procedure, the sample is fluidized in the cylinder. The side hole is then opened for 30 seconds, and the powder flowing out is caught in a beaker and weigh.

The spray factor is a combination of the expansion factor and the powder flow. Especially in dry flux application, where the material transport depends on fluidizing properties, the spray factor presents an important relative figure for powder evaluation.

To be continued …

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!