Filler Metal Management 1

Experimental

The effect of temperature on filler metal erosion was studied using an automotive radiator core.

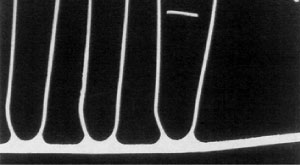

610 °C for 2 minutes - no thinning of the tube core

625 °C for 2 minutes - significant erosion of the tube core

In this case, joining progresses initially as expected. The cladding layer on the tube melts and flows by capillary action to the fin to tube joint and a normal fillet forms. However, as the peak brazing temperature is allowed to rise beyond the recommended maximum (605 °C) the following occurs:

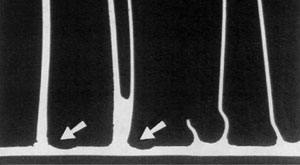

- The fluidity of the filler metal at the tube to header joint is increased and some of the liquid filler metal is released and flows to the nearest tube to fin joints.

- Excess filler metal at the tube to fin joints accelerates dissolution of the tube core adjacent to the fin, eroding the tubewall thickness.

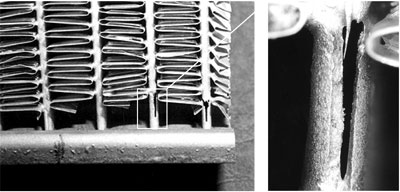

- The excess filler metal pool is then drawn by capillary action in between the fins, particularly where the finspacing is narrow. The fins are drawn together by the strong capillary forces, displacing the fin from its original fin to tube position.

- As the fins move together, drawing the filler metal pool from its original position, the denuded area is significantly reduced in cross sectional thickness.

In some instances the extent of filler metal erosion is so severe that the entire thickness of the tube is consumed resulting in catastrophic failures.

More about this topic in our next issue.

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!