On October 8th & 9th, 2019 – for the 18th time since 2001 – the Aluminium Brazing Seminar took place at Solvay Fluor in Hanover (Germany). There was a ‘full house’ with 31 participants from 12 countries – representing 15 companies – plus 5 Solvay participants joining this technical training.

Schlagwortarchiv für: Seminar

The Theory and Practice of the Flame- and Furnace-Brazing of Aluminium

![]()

Dates: October 8 & 9, 2019 in Hanover/Germany

Purpose of the Seminar:

The language of the seminar is English. It will take place in the Conference Center and laboratories of SOLVAY GmbH, in Hanover, Germany. It will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium. These are:

- The flame brazing of aluminium.

- Controlled Atmosphere Brazing (CAB) of aluminium heat exchangers with non-corrosive fluxes (NOCOLOK® Flux).

- The methodology of how to ensure that the brazing process selected is, indeed, the one that represents ‘best practice’.

Who should attend this two-day seminar?

- Technical staff who need to have a specific understanding of either one or both of the fine details of the technology of the brazing of aluminium with flames, and/or the NOCOLOK® furnace brazing process.

- Design and production engineers who are fabricating, or who are intending to fabricate, aluminium pipe-work assemblies and/or condensers and/or evaporators.

- Production Engineering Department Managers whose duties include day-to-day responsibility for the brazing of aluminium.

- Quality management personal of all levels in all departments including design, production, customer contract negotiations and standards including ISO 9001:2015

Watch the video of the Solvay Technical Training Seminar

Here you can find the detailed seminar program and registration.

And here the hotel booking form.

The Theory and Practice of the Flame- and Furnace-Brazing of Aluminium

Dates: October 9 & 10, 2018 in Hannover/Germany

Purpose of the Seminar:

The language of the seminar is English. It will take place in the Conference Center and laboratories of Solvay GmbH, in Hannover, Germany. It will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium. These are:

- The flame brazing of aluminium.

- Controlled Atmosphere Brazing (CAB) of aluminium heat exchangers with non-corrosive fluxes (NOCOLOK® Flux).

- The methodology of how to ensure that the brazing process selected is, indeed, the one that represents ‘best practice’.

Who should attend this two-day seminar?

- Technical staff who need to have a specific understanding of either one or both of the fine details of the technology of the brazing of aluminium with flames, and/or the NOCOLOK® furnace brazing process.

- Design and production engineers who are fabricating, or who are intending to fabricate, aluminium pipe-work assemblies and/or condensers and/or evaporators.

- Production Engineering Department Managers whose duties include day-to-day responsibility for the brazing of aluminium.

Watch the video of the Solvay Technical Training Seminar

Here you can find the detailed seminar programme and registration.

And here the hotel booking form.

The Theory and Practice of the Flame- and Furnace-Brazing of Aluminium

Dates: September 5 & 6, 2017 in Hannover/Germany

Purpose of the Seminar:

The language of the seminar is English. It will take place in the Conference Center and laboratories of Solvay GmbH, in Hannover, Germany. It will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium. These are:

- The flame brazing of aluminium.

- Controlled Atmosphere Brazing (CAB) of aluminium heat exchangers with non-corrosive fluxes (NOCOLOK® Flux).

- The methodology of how to ensure that the brazing process selected is, indeed, the one that represents ‘best practice’.

Who should attend this two-day seminar?

- Technical staff who need to have a specific understanding of either one or both of the fine details of the technology of the brazing of aluminium with flames, and/or the NOCOLOK® furnace brazing process.

- Design and production engineers who are fabricating, or who are intending to fabricate, aluminium pipe-work assemblies and/or condensers and/or evaporators.

- Production Engineering Department Managers whose duties include day-to-day responsibility for the brazing of aluminium.

Watch the video of the EABS Technical Training Seminar

Here you can find the detailed seminar programme and registration.

The Theory and Practice of the Flame- and Furnace-Brazing of Aluminium

Dates: September 6 & 7, 2016 in Hannover/Germany

Purpose of the Seminar:

This technical training seminar will be presented in the English language at the Conference Centre and laboratories of Solvay GmbH, in Hannover, Germany. It will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium. These are:

- The flame brazing of aluminium.

- Controlled Atmosphere Brazing (CAB) of aluminium heat exchangers with non-corrosive fluxes (NOCOLOK® Flux).

- The methodology of how to ensure that the brazing process selected is, indeed, the one that represents ‘best practice’.

Who should attend this two-day seminar?

- Technical staff who need to have a specific understanding of either one or both of the fine details of the technology of the brazing of aluminium with flames, and/or the NOCOLOK® furnace brazing process.

- Design and production engineers who are fabricating, or who are intending to fabricate, aluminium pipe-work assemblies and/or condensers and/or evaporators.

- Production Engineering Department Managers whose duties include day-to-day responsibility for the brazing of aluminium.

Watch the video of the EABS Technical Training Seminar

Here you can find the detailed seminar programme and registration.

On October 13th and 14, 2015, the European Association for Brazing and Soldering (EABS) together with experts from Solvay Fluor and Solvay Flux, has held the 14th annual Technical Seminar on the Theory and Practice of Flame and Furnace Aluminium Brazing – short: The Aluminium Brazing Seminar.

The delegates were representing technical staff, design and production engineers as well as production engineering managers from more than 20 companies. Key aspects and principles of aluminium flame and furnace brazing were presented during the event. The practical demonstrations included the ‘Safe-Flame-Process’ using a flame from a hydrogen generator, and a complete flux paste dispensing system suitable for several application methods.

37 interested participants from all over the world (14 countries) gathered for the two day training in Hanover, Germany.

Article from the Newsletter of our sponsor Solvay Fluor:

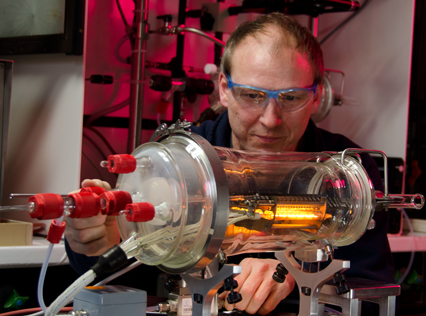

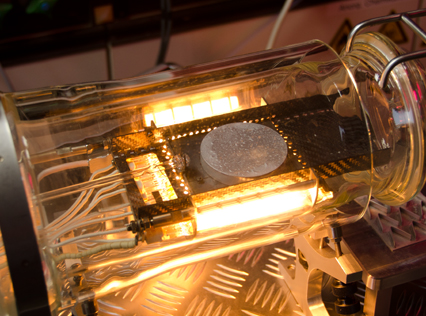

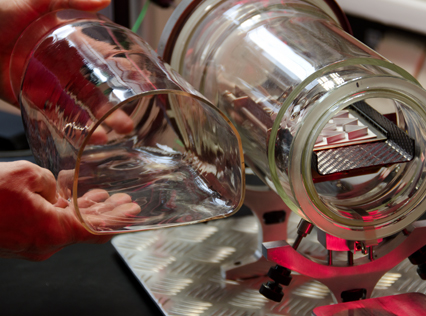

New glass brazing furnace in the NOCOLOK Technical Center

Many visitors to seminars, trade shows or videos are already familiar with the test glass brazing furnace in the NOCOLOK Technical Center. The unique furnace now has a big brother. All components of the new test furnace, except for the radiant heater, were developed in own production at Solvay.

The fluorine research workshop in Hannover has done an excellent job, “The construction of such a furnace is only possible with the tremendous expertise of the colleagues in the test workshop,” says Andreas Becker, a Solvay Fluor research employee. “With the new glass furnace, it is possible to braze larger objects, such as aluminium wafers for refrigerant test series for automobile producers.”

Specially developed software can capture every stage of the brazing process as high-resolution images – so that not even the tiniest detail of the brazing process can escape the testers. The new furnace saves energy and time – test brazing series with larger objects no longer require the much larger Camlaw brazing furnace at the Technical Center.

The next stage of development is already being planned: in a unique process Solvay’s glass blowers have succeeded in forming a square glass body, which offers even more space for larger items.

An overview of all services from the NOCOLOK Technical Center is offered in the new brochure, which is available for download.

The European Association for Brazing and soldering — EABS for short — together with experts from Solvay Fluor, holds technical training seminars in which the theory and practice of flame and furnace aluminium brazing are communicated in detail.

40 interested participants from all over the world gather for the two day seminar in Hannover, Germany: technical staff, design and production engineers as well as production engineering managers.