Technical Information by Daniel Lauzon

Manufacturing Processes

By the early nineties, aluminum had already almost completely replaced copper/brass in radiators at the Ford Motor Company. Ford had gone through mass production of mechanically assembled radiators starting in 1982 and introduced vacuum brazing in 1983. In 1989, Winterbottom reported,

…”the manufacturing capability and the superior corrosion resistance of aluminum was well established, and the competition between copper/brass and aluminum in the radiator application essentially ended.” (5)

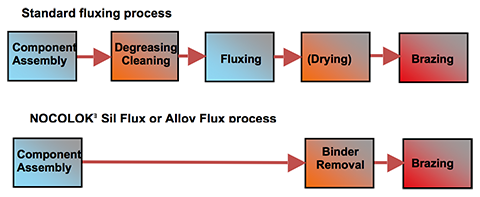

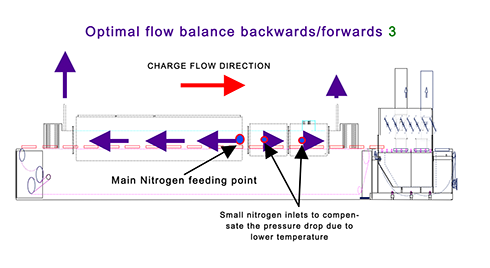

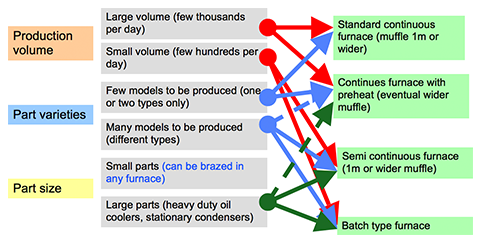

By the mid-nineties, vacuum brazing was becoming less popular due to its high maintenance furnaces and less forgiving nature. Vacuum brazing was giving way to the more popular noncorrosive flux brazing process, also known as Controlled Atmosphere Brazing or CAB. Today, CAB brazing is the preferred process for manufacturing automotive heat exchangers worldwide. In Solvay’s estimate, there are now more than 600 CAB brazing furnaces in the world with more than 100 more in plan.

No discussion on the differences between copper/brass and aluminum radiator manufacturing processes would be complete without bringing up the topic of CuproBraze®. It is a new process for manufacturing copper/brass radiators developed by the International Copper Association (ICA) in conjunction with Outokumpu Copper Strip AB of Sweden (6). This process was surely developed to combat copper’s decline in the automotive heat exchanger markets and does appear to offer many advantages over the traditional copper/brass “soft-soldering” technology. But alas, no in-roads have been made in passenger vehicle radiators and the new technology is has found a niche in some truck and off-road vehicle markets.

Environmental and Recyclability Considerations

From an environmental perspective, there are no special considerations for adopting the noncorrosive flux brazing process. Unlike conventional Cu/brass radiator technology, there are no heavy metals employed in any part of the process, including the flux, lubricants, cleaning solutions and alloys. The wastewater stream contains some fluorides and the exhaust effluent from the furnace must be scrubbed due to the low level (ppm level) formation of HF gas, but these have not prevented the worldwide successful commercialization of the technology.

There are also no major recycling issues with aluminum radiators. The filler metal or ‘solder’ used in aluminum heat exchanger manufacturing is, after all, just another aluminum alloy. The common alloying elements such as silicon in the filler metal do not pose any issues and brazed aluminum heat exchangers are recyclable for use in the secondary aluminum industry (e.g., castings) or at the very least as high-value scrap.

Performance and Reliability

There are very few references in the literature showing side by side comparisons of reliability and performance characteristics of Cu/brass and aluminum heat exchangers for the automotive industry. Years ago, Calsonic introduced aluminum radiators to the agricultural machinery market in Japan and did publish some side by side reliability data (7). Calsonic’s comparison study included corrosion testing, pressure cycling, vibration testing and cooling system performance. The results showed a 30 percent reduction in weight compared to conventional copper radiators and better performance in actual use conditions.

Other Applications

Non-corrosive flux brazing of aluminum is used primarily for automotive heat exchanger manufacturing. However, there are several other small markets where non-corrosive flux brazing is used:

- In the manufacturing of small household appliances where the aluminum heating elements for coffee makers, electric tea kettles, clothes dryers and clothes irons are brazed to a substrate.

- In the manufacturing of high-end pots and pans where the stainless steel pot/pan is brazed to an aluminum base plate.

- In refrigerators where copper or aluminum tubing is brazed to aluminum roll-bond panels.

- In heat sinks for electronics

Future Developments

It is this author’s opinion, based on more than 30 years experience in the automotive heat exchanger industry that aluminum is here to stay. There is no indication from the passenger vehicle OEM market that copper/brass will make a comeback. On the materials side, the aluminum suppliers will continue to look for ways to improve strength and corrosion resistance to down-gauge even further. On the manufacturing side, there is no sign that flux usage will disappear. What is foreseen is a more efficient use of flux in terms of selective deposition – prefluxing of select components using binders – in order to minimize waste and flux consumption. In 1995 when one spoke of non-corrosive type fluxes, there was really one type of flux chemistry available. Today, several types of fluxes are available, from fluxes capable of tackling higher magnesium contents, to fluxes capable of generating sacrificial corrosion layers in-situ. There are fluxes capable of generating filler metal in-situ and there are fluxes dedicated for electrostatic fluxing equipment and so on. There are also continuous improvements made to controlled atmosphere brazing furnaces for aluminum to improve efficiency and throughput. We will continue to see aluminum radiators made cheaper, smaller and stronger.

References:

- Gray, Alan., The Growth of Aluminium in Automotive Heat Exchangers, 3rd International Congress – Aluminium Brazing, Düsseldorf, 2004.

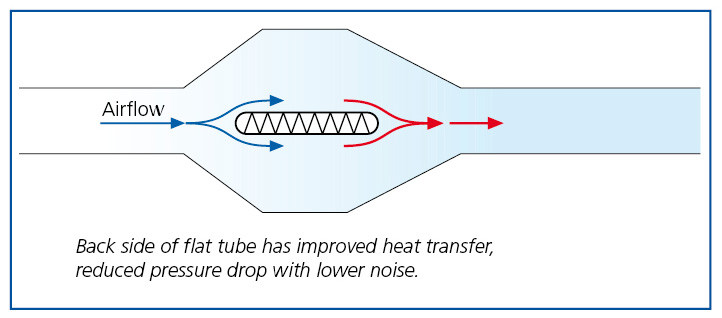

- Ross, Gary R, Curtindale, William D, Controlled Atmosphere Brazing of Roll-formed Folded Aluminum Heat Exchanger Tubes, Therm Alliance International Invitational Aluminum Brazing Seminar, 1999.

- Jackson, A., Price H.C.R., High Performance Core Technology for Brazed Automotive Radiators, VTMS C496 / 076, 1995.

- Scott, Arthur C., Corrosion Performance of Long-Life Automobile Radiators, VTMS3, 971857, 1997.

- Winterbottom, Walter L., The aluminum auto radiator comes of age, Advanced Material and Processes, pp 55-56, Vol. 5, 1990.

- www.cuprobraze.com

- Ochiai, H., Hataura, K., Application of Non-Corrosive Flux Brazing Aluminum Radiator to Agricultural Machinery, SAE Conference paper 911298, 1991.