The NOCOLOK International Brazing Seminar will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium.

Schlagwortarchiv für: Rules

The NOCOLOK International Brazing Seminar will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium.

The Theory and Practice of the Flame- and Furnace-Brazing of Aluminium

![]()

Dates: October 8 & 9, 2019 in Hanover/Germany

Purpose of the Seminar:

The language of the seminar is English. It will take place in the Conference Center and laboratories of SOLVAY GmbH, in Hanover, Germany. It will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium. These are:

- The flame brazing of aluminium.

- Controlled Atmosphere Brazing (CAB) of aluminium heat exchangers with non-corrosive fluxes (NOCOLOK® Flux).

- The methodology of how to ensure that the brazing process selected is, indeed, the one that represents ‘best practice’.

Who should attend this two-day seminar?

- Technical staff who need to have a specific understanding of either one or both of the fine details of the technology of the brazing of aluminium with flames, and/or the NOCOLOK® furnace brazing process.

- Design and production engineers who are fabricating, or who are intending to fabricate, aluminium pipe-work assemblies and/or condensers and/or evaporators.

- Production Engineering Department Managers whose duties include day-to-day responsibility for the brazing of aluminium.

- Quality management personal of all levels in all departments including design, production, customer contract negotiations and standards including ISO 9001:2015

Watch the video of the Solvay Technical Training Seminar

Here you can find the detailed seminar program and registration.

And here the hotel booking form.

The Theory and Practice of the Flame- and Furnace-Brazing of Aluminium

Dates: October 9 & 10, 2018 in Hannover/Germany

Purpose of the Seminar:

The language of the seminar is English. It will take place in the Conference Center and laboratories of Solvay GmbH, in Hannover, Germany. It will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium. These are:

- The flame brazing of aluminium.

- Controlled Atmosphere Brazing (CAB) of aluminium heat exchangers with non-corrosive fluxes (NOCOLOK® Flux).

- The methodology of how to ensure that the brazing process selected is, indeed, the one that represents ‘best practice’.

Who should attend this two-day seminar?

- Technical staff who need to have a specific understanding of either one or both of the fine details of the technology of the brazing of aluminium with flames, and/or the NOCOLOK® furnace brazing process.

- Design and production engineers who are fabricating, or who are intending to fabricate, aluminium pipe-work assemblies and/or condensers and/or evaporators.

- Production Engineering Department Managers whose duties include day-to-day responsibility for the brazing of aluminium.

Watch the video of the Solvay Technical Training Seminar

Here you can find the detailed seminar programme and registration.

And here the hotel booking form.

The Theory and Practice of the Flame- and Furnace-Brazing of Aluminium

Dates: September 5 & 6, 2017 in Hannover/Germany

Purpose of the Seminar:

The language of the seminar is English. It will take place in the Conference Center and laboratories of Solvay GmbH, in Hannover, Germany. It will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium. These are:

- The flame brazing of aluminium.

- Controlled Atmosphere Brazing (CAB) of aluminium heat exchangers with non-corrosive fluxes (NOCOLOK® Flux).

- The methodology of how to ensure that the brazing process selected is, indeed, the one that represents ‘best practice’.

Who should attend this two-day seminar?

- Technical staff who need to have a specific understanding of either one or both of the fine details of the technology of the brazing of aluminium with flames, and/or the NOCOLOK® furnace brazing process.

- Design and production engineers who are fabricating, or who are intending to fabricate, aluminium pipe-work assemblies and/or condensers and/or evaporators.

- Production Engineering Department Managers whose duties include day-to-day responsibility for the brazing of aluminium.

Watch the video of the EABS Technical Training Seminar

Here you can find the detailed seminar programme and registration.

The Theory and Practice of the Flame- and Furnace-Brazing of Aluminium

Dates: September 6 & 7, 2016 in Hannover/Germany

Purpose of the Seminar:

This technical training seminar will be presented in the English language at the Conference Centre and laboratories of Solvay GmbH, in Hannover, Germany. It will provide information concerning the manufacturing practices commonly used for brazing operations and, in particular, will address the three fundamental aspects of the industrial-scale brazing of aluminium. These are:

- The flame brazing of aluminium.

- Controlled Atmosphere Brazing (CAB) of aluminium heat exchangers with non-corrosive fluxes (NOCOLOK® Flux).

- The methodology of how to ensure that the brazing process selected is, indeed, the one that represents ‘best practice’.

Who should attend this two-day seminar?

- Technical staff who need to have a specific understanding of either one or both of the fine details of the technology of the brazing of aluminium with flames, and/or the NOCOLOK® furnace brazing process.

- Design and production engineers who are fabricating, or who are intending to fabricate, aluminium pipe-work assemblies and/or condensers and/or evaporators.

- Production Engineering Department Managers whose duties include day-to-day responsibility for the brazing of aluminium.

Watch the video of the EABS Technical Training Seminar

Here you can find the detailed seminar programme and registration.

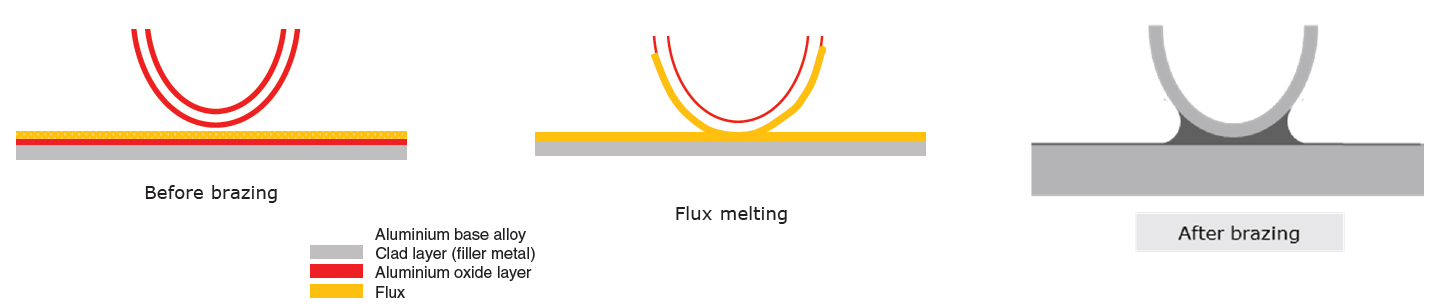

Aluminium joining – Brazing ‐ Flux function

What is brazing?

Brazing is the joining of metals using a molten filler metal. On melting, the filler metal spreads between the closely fitted surfaces, forms a fillet around the joint and on cooling forms a metallurgical bond. By technical definition ‚brazing‘ is a joining process in which the filler metal melting temperature is above 450°C, but below the melting point of the metals to be joined.

Aluminium brazing ‐ How does it work?

An aluminium oxide layer is formed instantly on aluminium in the presence of oxygen. This oxide layer has to be removed before brazing and the formation of a new oxide layer has to be prevented. The oxide layer is chemically dissolved by a FLUX.

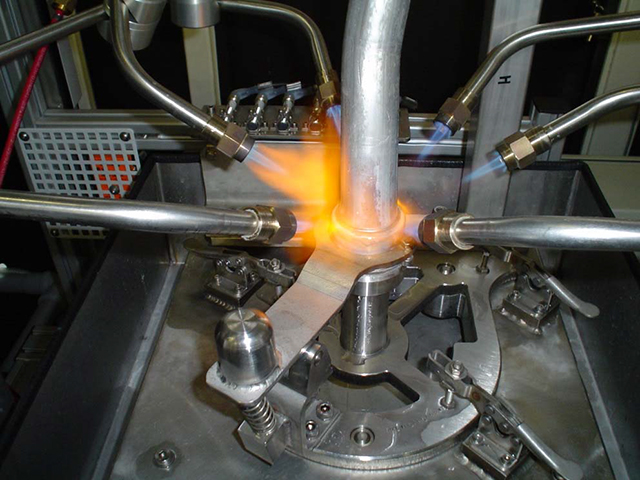

Aluminium joining – Flame Brazing

Flame (torch) brazing of aluminium involves locally applied heat typically generated by a slightly reducing oxy‐acetylene or oxy‐natural gas flame. (Gas mixture is preferred as it is cheaper and more comfortable).

Care must be taken to ensure even heat distribution. As with other aluminium brazing processes, close temperature control is important – it`must be closely monitored as there is no colour change in the aluminium to indicate temperature.

Aluminium joining – Basic Requirements

CORRECT FLUX / CORRECT FILLER METAL / CORRECT DIFFUSION OF FILLER METAL

The first requirement of an Aluminium brazing is to be chemically effective.

Fluxes are categorized as active (corrosive) and inert (noncorrosive)

CORRECT BRAZING TEMPERATURE

Between liquidus and solidus of filler metal

Decide how to manage the small thermal window between the melting temperature of the brazing filler metal and thermal damage to the base metals

BRAZING THROUGH CAPILARITY / RIGHT GAP OF THE BRAZING JOINT

Apart from the selection of flux and filler metal, important process parameters are the cleanliness and proper geometrical alignment of the individual components.

To be continued…

1. Preparation and Application

This article provides information about the application of binder systems for NOCOLOK Flux.

Solvay offers three concepts for flux binder application:

- NOCOLOK Binder (water-soluble) / NOCOLOK Thickener (water-soluble)

- NOCOLOK System Binder (water-based)

- NOCOLOK Flux plus Binder Mixture (water-based)

These products can be used in water-based NOCOLOK Flux slurries to improve flux particle adhesion. This is of particular interest for fluxing of pre-formed components prior to assembly in order to reduce flux fall-off and dust formation. Binders are also helpful to pre-coat certain areas with specific flux loads. All binder mixtures can be applied on external and internal surfaces.

During the brazing cycle, these binders will completely evaporate (mostly between 350 and 400°C). When used as described below, there will neither be detrimental interactions between the binder and the flux, nor between the binder and the aluminum surfaces. Trials have shown that even at four-times the standard flux load with a binder mixture there was still no surface discoloration after brazing.

2. General Comments

The surface areas to be coated with binder mixtures must be free of lubricants, oils, dirt, and dust. Means of application include spraying, dipping, and brushing.

All NOCOLOK Flux binder mixtures can be applied by spraying with a suitable spray gun (1.4 mm – 1.6 mm) at approximately 3 – 5 bar pressure.

The surface temperature should be at least 10°C.

When binders are used for flux application, the recommended flux load for good brazing results is the same as it is for the standard process (i.e. between 3 – 5 g/m2). The thickness of the binder coating is usually between 10 – 30 μm.

Drying can be done in air – requiring approximately 15 – 20 minutes at room temperature for the coating surface – and 50 – 60 minutes before the parts can be handled. Oven and forced convection drying is feasible too: at 50 – 80 °C, parts will dry within 5 – 20 minutes.

Please refer to the MSDS for detailed information regarding the safe handling of the product.

3. Preparation of Binder Mixtures

For all binder concepts and preparations, the mixtures should be prepared or opened immediately before consumption.

To prepare a mixture free of agglomerates and to achieve best coating results, the following procedures must be observed for either binder concepts:

- NOCOLOK Binder / NOCOLOK Thickener

- 45 parts (wt%) de-ionized water (as used for preparing standard flux slurries) is mixed thoroughly with

- 15 parts (wt%) NOCOLOK Binder (water-soluble) and

- 5 parts (wt%) NOCOLOK Thickener (water-soluble).

- Once the first three components are completely homogenized,

- 35 parts (wt%) NOCOLOK Flux powder are added successively under continuous agitation.

- NOCOLOK System Binder

- NOCOLOK System Binder (water-based) already contains the binder and thickener component as well as water. Consequently, only NOCOLOK Flux powder must be added.

- 65 parts (wt%) NOCOLOK System Binder (water-based) plus

- 35 parts (wt%) NOCOLOK Flux.

- NOCOLOK Flux plus Binder Mixture

- NOCOLOK Flux plus Binder Mixture (water-based) is a ready-for-use preparation containing NOCOLOK Binder, NOCOLOK Thickener and NOCOLOK Flux powder.

If necessary, the mixtures can be passed through a sieve prior to use. This will remove any potential agglomerates.

Prior to use the flux powder in the mixture must be suspended. The thickener will prevent the flux powder from settling too fast, however, when stored for some time or diluted, the mixture must be well shaken before spraying.

The binder component is activated by oxygen from air. Once sprayed and dried, the product cannot be recycled or reused.

Any remaining flux / binder mixture should be stored in an airtight and sealed container. We recommend consuming the mixtures within one week after mixing.

4. Additional Information:

- NOCOLOK Binder, -Thickener, and –System Binder are compatible for standard NOCOLOK Flux, -LM Flux, -Cs Flux, and -Sil Flux. They are not suitable for NOCOLOK CB Flux and -Zn Flux due to chemical reactions between these fluxes and the ingredients.

- The formulations (mixing ratios) provided in Solvay’s technical information sheets and brochures are intended as general recommendations – They provide the best basis for automated spray application and have been tested with good brazing results.

- The recipes can be adjusted to specific application needs by changing the mixing ratios within certain ranges.

- A well balanced ratio of binder and thickener to flux in the mixtures is important for good brazing performance:

- Higher binder ratios result in a harder coating layer and stronger flux adhesion. But they require more care for the binder removal step.

- Very high binder and/ or thickener ratios increase the organic content in the mixture – which may result in carbon residues (discoloration) after brazing.

- It is possible to reduce and/ or to increase the water content of the mixtures – resulting in higher respectively lower viscosity.

- Water dilution will cause less wetting action and reduced adhesion.

- A surfactant (wetting agent) is part of the binder formulation – providing uniform coating, and – compensating (to some extent) for surfaces not cleaned prior to application.

- Thickener is used for adjusting the viscosity and to keep the flux powder longer in suspension – This provides better performance in spray application. Nevertheless, formulations can be prepared and used without the addition of thickener.

- Cleaning before binder-based flux application is recommended – but not mandatory.

- A clean surface can be coated more easily and the flux adhesion will be better.

- Residual oils and lubricants are reducing binder activity and require higher flux load.

- Higher surfactant levels can compensate for some contamination – but result in more foaming.

5. Binder Flux Mixing Ratios

- The standard composition is 35% NOCOLOK Flux, 15% NOCOLOK Binder, 5% NOCOLOK Thickener and 45% water. If a product with lower flux ratio is wanted (i.e., with only 10% flux), the composition must be modified. Right now, we are proposing 10% flux, 8% binder, 2% thickener and 80% water. There is only limited experience with this composition, and we are a little concerned. The reasons for our concerns are as follows:

- With 35% flux, the ratio of flux to binder/ thickener on the surface of the headers is sufficient to combat the effects of the high organic content. Also, 15% binder has reasonable adhesion characteristics.

- At 10% flux, the ratio of flux to binder/ thickener must be modified; otherwise there may not be sufficient flux to combat the high organic content. This is why we propose to reduce the binder and thickener to 8% and 2%, respectively. In other words, too much binder/ thickener and not enough flux may lead to black deposits on the headers after brazing and/ or difficulties in brazing.

6. Warehousing Considerations and Shelf Life

- Under standard storage conditions, the shelf life is up to 12 months and probably longer. Standard storage conditions means that the product was stored at less than 30°C, as suggested in the MSDS.

- The binder product can be stored at a temperature higher than 30°C, but the shelf life will shorten due to premature aging. Therefore, we recommend that the binder products be consumed within six months, if the storage temperature is a constant 40°C. This is not based on experimental data, but on general knowledge of water based polymer systems and adhesives. Any product stored at a temperature higher than 40°C should be consumed more quickly.

- Under no circumstances should the binder products, in their original packaging, be exposed to a temperature of 60°C or above. We suspect that polymerization will occur, agglomerates will form and the performance will drop.

7. Thermo-Gravimetric Analysis (TGA) for Binder Flux

Please refer to the flyer “NOCOLOK Flux Application with Binders”.

8. Recommendations for Reducing Costs

- Is not possible to only mix the binder, thickener and flux and just add the water on site. Without the water, the flux/ thickener/ binder mixture forms a rubbery-like substance that is very difficult to work with.

- The least expensive option is to purchase the binder and thickener separately and do mixing of all ingredients on site. The most convenient option is to have a ready-mix, ready-to-use product supplied.

- Please see above for additional recommendations for mixing.

Summary

The article was written on the basis of frequently asked questions from companies which either wanted to start a new all-aluminium brazing production of heat exchangers or wanted to convert from copper and aluminium mechanical assembly design to all-aluminium brazed parts. The questions were grouped into three main categories: Equipment (emphasis on assembling process), Process (emphasis on different fluxes and fluxing methods) and Corrosion.

Specific production challenges are also presented, which are important not only to newcomers of all-aluminium brazed heat exchangers, but to established companies as well. These include typical brazing problems such as managing leaks and the basics of brazing copper to aluminium. These topics are discussed by their relevance to the brazing parameters and their role in successful brazing.

Content:

- Introduction (in this issue)

- Equipment (in this issue)

- Brazing process (in August issue)

- Brazing copper to aluminium (in September issue)

- Corrosion resistance (in September issue)

- Summary (in September issue)

1. Introduction

Brazing Furnace

Increasing environmental concern has identified the air conditioning and refrigeration industry as one of the contributors to the greenhouse effect and ozone depletion.

Accordingly to [1] 15% of all electricity consumption in the developed world is used by the air conditioning and refrigerator industry. Increasing the efficiency of these heat transfer systems has the positive impact of decreasing electricity consumption and therefore the overall emission of CO2. The advantages of all aluminium brazed condensers in an air conditioning system are well described in [2]. For example one such case study [3] allowed for saving about 2700 USD during 6 months. The above advantages are currently well recognized by both the air conditioning manufacturers and their end users. It is our observation that the majority of the companies in the HVAC industry which have started or are about to start production of aluminium brazed heat exchangers have only limited experience with aluminium brazing; therefore providing them with maximum possible technical assistance from the supplier side is of high importance.

This article was written on the basis of our contacts with such companies having an aim to offer some assistance to all newcomers and companies facing some troubles with their new type of production.

2. Equipment

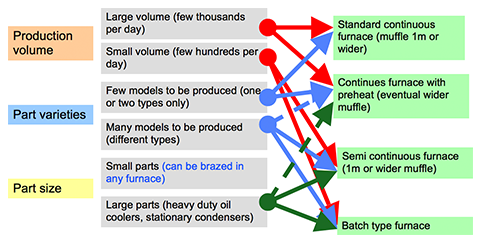

In most cases, the first question from a company that wants to start a new aluminium brazing activity is: “What kind of furnace should I buy?”

It is a complex issue which mainly depends on size of the products, its diversity and overall planned production volume. The general principles for the choice of the brazing furnace are shown in Fig. 1. It should be pointed out that the furnace manufacturers will make a brazing furnace customized to particular requirements of a given client.

Fig. 1: Basic principles for brazing furnace choice

Assembling units

In many cases the companies which are starting production of all aluminium brazed heat exchangers have been producing copper brazed heat exchangers. Therefore the natural question is: ”Can I use the same equipment which is used for copper units?”

The straight forward answer is: No! Aluminium requires high precision for assembling (recommended gap size is 0.1 to 0.15mm), which is hardly ever achieved for brazing copper parts. Also one should remember that any copper contamination on aluminium can cause catastrophic brazing failures (holes).

The process of component assembly can be done on a simple manual stacker or on machines with varying degrees of automation through to fully automated units. The level of automation should be mainly determined by the planned production volume, but also other factors such as local labour costs should also be considered.

Basic requirements for a manual assembling unit:

- Cores must be assembled on a perfectly flat heavy steel plate

- After laying out the tubes and fins, the tubes must be pushed precisely into position determined by the slots in the headers.

- To secure the above requirement:

- movement of the pusher must be allowed only in one direction (no side or up movement),

- travel distance must be accurately controlled – e.g. by mechanical block on the pusher,

- it is useful to have a special distances between tubes to secure the right spacing for each header slot,

- the vertical alignment of the tubes must be secured either by steel plate or by hammering the tubes with a special pad.

- Threading the headers on the tubes should be done in one single action which does not allow for any side or vertical deflection of the headers.

- After threading the headers the fixtures should be assembled and the tube pusher released.

The process of the part assembly is invariably connected with fixtures; these are the steel elements which hold the parts together during brazing and then removed after brazing. The most frequently asked question is: ”What should be the design of the brazing frames/fixtures?”

Basically there are rigid and elastic designs which allow for some expansion when the core is heated. For larger cores elastic design is preferred. This type of fixture is reusable, also known as a permanent fixture and can go through the brazing cycle several hundred times. Apart from that we could use single usage fixtures, known as disposable fixtures and these include steel wire and steel bands. The multi-use fixtures must be made of stainless steel and in most cases the single use fixtures are usually made of ordinary low carbon steel.

Fig. 2: Example of rigid and elastic fixtures

When designing the length of the fixture (distance marked in red as Ls in fig. 2, one must remember thatthere is a difference in thermal expansion coefficient between aluminium and steel. To compensate for this, the following assumption is made: The length of the steel fixture at brazing temperature must be equal to the nominal width of the aluminium exchanger at brazing temperature. On this basis, an equation can be used describing the linear change of dimensions with temperature.

Ls(1 + αstΔt) = Lo(1 + αalΔt)

Where:

Ls – length of steel fixture,

αst – thermal expansion coefficient for the fixture material,

αal – thermal expansion coefficient for aluminium,

Δt – Increase of the part temperature during brazing,

Lo – Nominal width of the part.

As an example, for a part having width of 900 mm and nominal tube spacing of 8 mm, solving this equation and taking into account the fact that after assembly there must be some pressure exerted by the fixture on the part, the length of the fixture should be 907.5 mm and the fin height 8.08 mm. The longer steel fixture is compensated by the increased fin height. It also means that after assembly the part will have a slightly barrel-like shape (bowed out at the sides).

The question: ”What final checks are required for brazed parts?”is also connected to equipment purchases. All brazed parts must be checked for leak tightness. The most simple method is the so called “under water test”. In this case the part is pressurized with air and lowered into a water bath to look for bubbles. However some end users require more accurate and reliable methods. In the automotive industry it is common to check condensers for leaks with high pressure and extremely sensitive helium leak detection devices.

Each product should be accepted by the end user. In every case the scope of acceptance tests should be agreed to between the manufacturer and the end users. Typical tests include burst pressure, thermal cycling and of course standard ones for heat transfer efficiency and pressure drop. As a general rule it can be said that all aluminium parts should meet all the requirements applied to copper/brass parts.

References:

1. Hans W. Swidersky, “Brazed Aluminium Heat Ex-changers for the Refrigeration and Air Conditioning Industry”, APT Aluminium News, 1-2009

2. Bjørn Vestergaard, “Brazed Aluminium Heat Ex-changers – Ask for the inexpensive features”, Seminar “Aluminium Process-Technology for HVACR Industry” Vienna, March 21st-23rd, 2007

3. Case Study – Harris County Sheriff’s Building, “Carrier Turn to the Experts” 2006 Carrier Corporation 05/06 04-811-10206

Will be continued…

In recent years, the topic of what to do with wastewater from fluxing operations has gained a lot of attention in light of heightened environmental awareness and compliance. Years ago, wastewater from cleaning slurry booths, waste flux slurries etc. were simply diluted and dumped down the drain. Some manufacturers are still following this practice, but it is become less and less common. Today, the heat exchanger manufacturers are faced with what to do with wastewater more and more.

Some manufacturers collect the waste slurries and effluent from cleaning out the fluxing stations and allow the flux to settle out. The water phase is then decanted and collected until a sufficient volume is collected. At that point, a waste disposal company is called in to collect and treat the contaminated water. This is an expensive, but in many cases a necessary option. If the collected water is relatively clean and not contaminated with oil, it may be reused to top up flux slurries. The only problem here is that one must be certain that there are no other contaminants in the wastewater other than flux ions. If there are other contaminants (and there almost certainly will be), tests should be performed to ensure that these will not in any way interfere with the brazing process.

Solvay Fluor also developed a continuous process to reuse and recycle wastewater in a fluxing operation. It is based on the principles described above, only in a continuous fashion:

Lauzon, D.C., Swidersky, H.W., “Methods for Eliminating Wastewater from Flux Slurries in Non-Corrosive Flux Brazing”, VTMS 2001-01-1764, pp 649-654, 2001.