Flame Brazing Technology – Part 4

What is critical

Have a clean surface (free of dust, grease)

Heat the joint evenly to brazing Temperature

Choose the right brazing alloy for the job (Mg content !)

Select the appropriate flux to remove the oxide skin from the faying surfaces of the joint

Use a capillary gap of the appropriate size

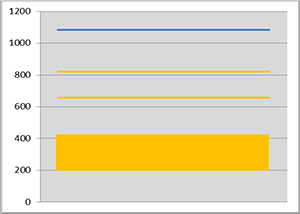

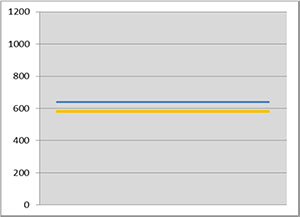

ALUMINIUM BRAZING – Correct brazing temperature

Melting point of copper 1084°C

Copper‐phosphorus alloy

- Elgalin Cu87 657°C ‐ 687°C

- Elgalin Cu93 710°C – 820°C

No flux necessary

Brazing temperature is below the melting

point of base material

Melting point of aluminium 630‐660°C

Aluminium‐Silicon alloy

- AlSi12 577°C – 585°C

Flux is necessary

Brazing temperature is very near the

melting point of base material

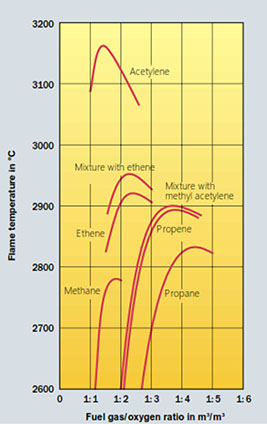

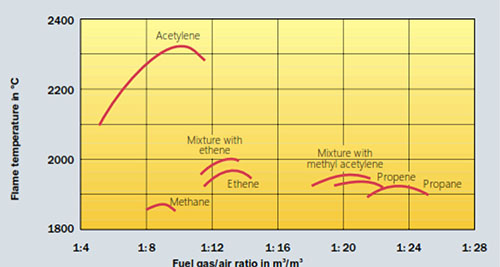

ALUMINIUM BRAZING – Correct brazing temperature ‐ flame

Acetylene + O2 3170°C

Propane + O2 2830°C

Natural gas + O2 2780°C

Acetylene + compressed air 2300°C

Propane + compressed air 1900°C

Natural gas + compressed air 1850°C

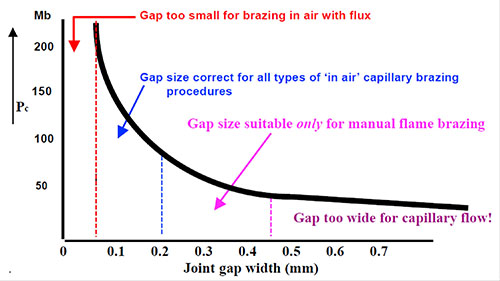

CAPILLARITY – right gap of the brazing joint

Capillary action works with gap between 0.05 and 0.2mm

Preciseness is essential for Al brazing.

Preciseness is essential for Al brazing.

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!