Welcome to the aluminium brazing blog site. We will regularly be publishing articles about aluminium brazing in this blog and we look forward to your comments, remarks and questions. Behind the scenes in this blog are the specialists for aluminium brazing from Solvay Fluor. This blog is a corporate blog and offers you new, additional ways to communicate with us.

One of the largest potentials to increase efficiency of heat exchangers lies within the heat-transfers: reducing condensing temperatures by 3 °K will improve overall system efficiency by approx. 10 % for a standard R 410 A air conditioning cycle. A minimization of the temperature difference between the air flows and the phase change temperatures of […]

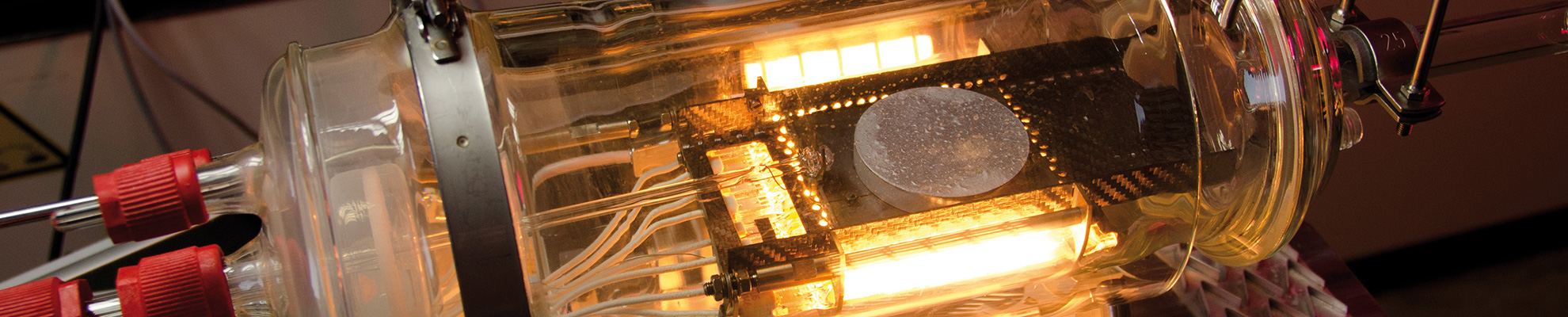

NOCOLOK® Flux is the world’s most widely used flux for aluminium brazing in a controlled atmosphere. Well-proven in the automotive industry, NOCOLOK® Flux is also increasingly used for brazing aluminium coolers for air conditioning and refrigeration systems. In the well-known standard applications NOCOLOK®Flux is not corrosive. To improve the positive properties under extreme conditions even further, Solvay […]

NOCOLOK® Cs is a special mixture that is intended for brazing Al alloys with a higher Mg content. By adding Mg to the alloy (types 6000 or 3000) higher material- and pressure resistance as well as better machine processing is now given, compared with NOCOLOK® standard Flux which could tolerate only low Mg contents. During brazing, Mg […]

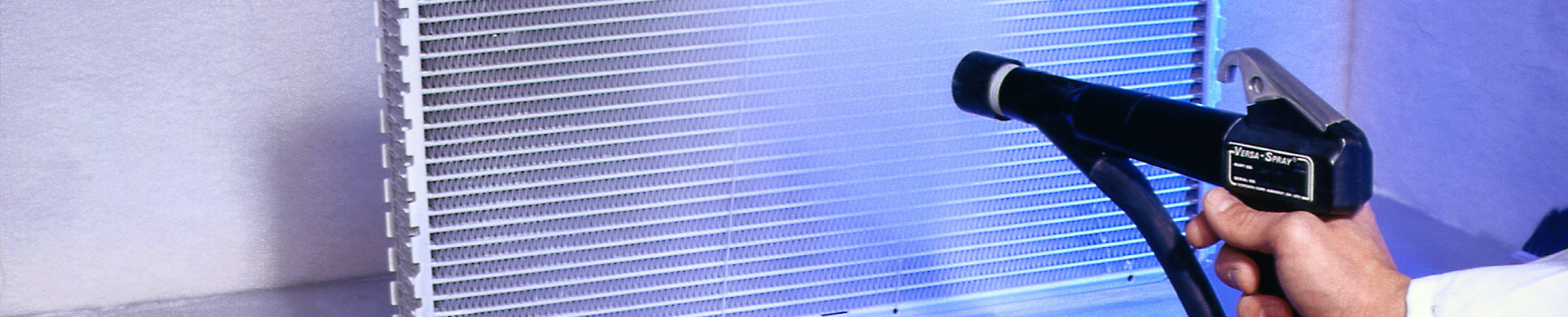

1. Have a clean surface 2. Heat the joint evenly to brazing Temperature 3. Choose the right brazing alloy for the job 4. Select the appropriate means of removing the oxide skin from the faying surfaces of the joint 5. Use a capillary gap of the appropriate size 6. Apply the brazing alloy to the […]