Welcome to the aluminium brazing blog site. We will regularly be publishing articles about aluminium brazing in this blog and we look forward to your comments, remarks and questions. Behind the scenes in this blog are the specialists for aluminium brazing from Solvay Fluor. This blog is a corporate blog and offers you new, additional ways to communicate with us.

The general appearance of NOCOLOK® brazed parts can range from relatively bright to light grey depending on the flux loading and furnace dew-point. When either is increased excessively over recommended levels, the appearance moves towards the grey colour. The flux residue usually can not be seen by the naked eye, however, it is visible under […]

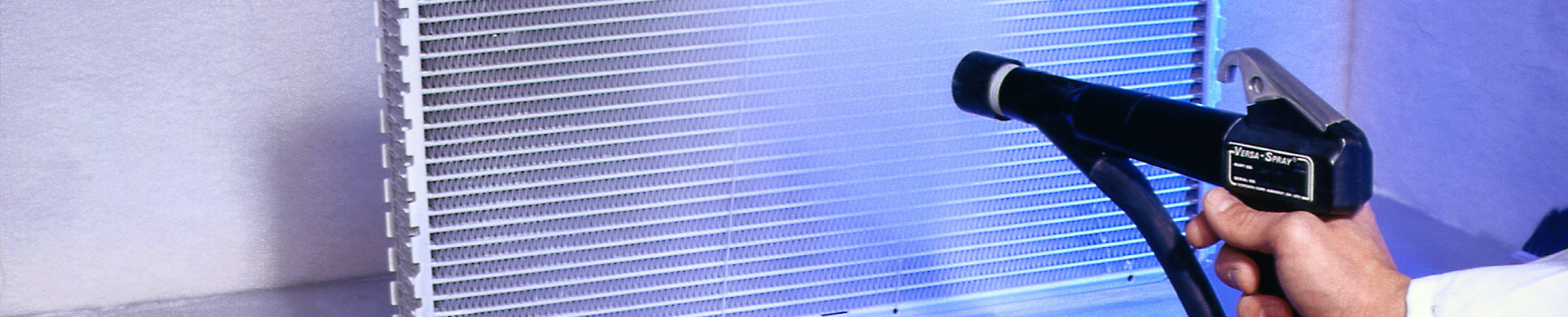

Very often, heat exchanger manufacturers increase the flux loading on components to be brazed to compensate for furnace atmosphere or other process related deficiencies. The flux is an excellent “band-aid” and can be used as such, but only while the true problems are located and rectified. Long term use of higher than recommended flux loads […]

The theoretical amount of flux required to dissolve a 100 Å oxide film is about 0.02 g/m2 (1 Å = 10-10 m = 0,1 nm). For a 400 Å film, still only 0.08 g/m2 flux is required. These do not take into account losses to moisture, oxygen or poisoning of the flux by Mg alloy […]

Based on currently available information, there is no simple cleaning method for flux residues by washing or dissolving – i.e. there is no suitable solvent or chemical solution – without attacking (corroding) the substrate material as well. Mechanical Cleaning Usually, removal of flux residue can only be done by mechanical means. From solid surfaces and […]

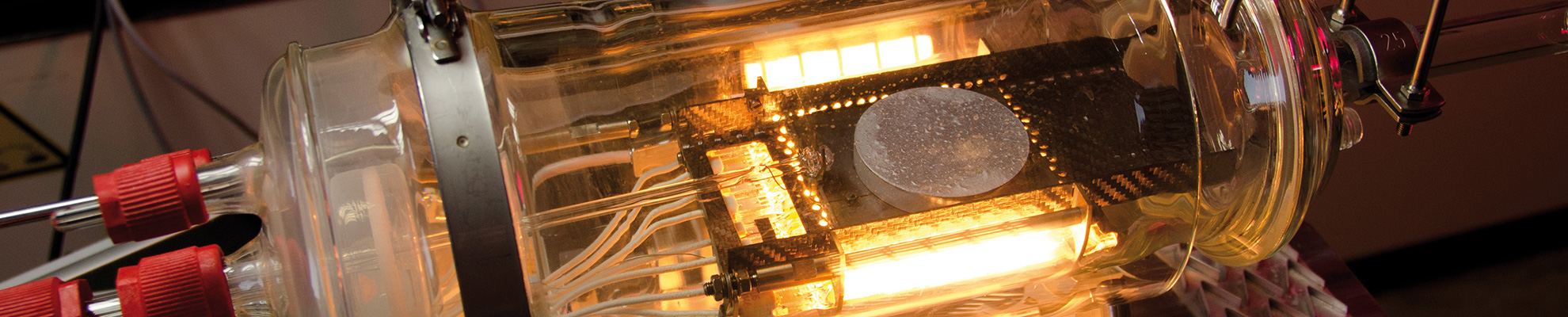

Dust and dirt, condensates, lubricants and oils must be thoroughly removed. If the metal work pieces are poorly prepared, the flux will not spread evenly and the flow of filler alloy will be haphazard: it will either not spread properly or will discolour. The consequence would be an incomplete joint. The first step is therefore: […]

When brazing aluminum to stainless steel using: a) NOCOLOK® Flux and Al-Si filler alloys are suitable or b) alternatively CsAlF-Complex flux (melting range between 420 and 480°C) and Zn-Al filler alloys. Regarding a): Brazing of aluminum to stainless steel works both with NOCOLOK® Flux + Al-Si filler alloy and with NOCOLOK® Sil Flux. After the […]

The following article provides some answers on general questions regarding the use of NOCOLOK Sil Flux for manufacturing pots and pans. What is the NOCOLOK Sil Flux quantity (per m²) required for sandwich brazing or pressure cookers (stainless steel to aluminium)? The recommended load for NOCOLOK Sil Flux is approximately 15 to 25 g/m². Brazing aluminium to stainless […]

Brazing sheet comprises of a core alloy clad on 1 or 2 sides with a lower melting aluminum-silicon (Al-Si) alloy. This thin layer, usually makes up 5 % to 10 % of the total thickness of the brazing sheet. It melts and flows during the brazing process, to provide upon cooling a metallic bond between […]