Sil Flux Brazing

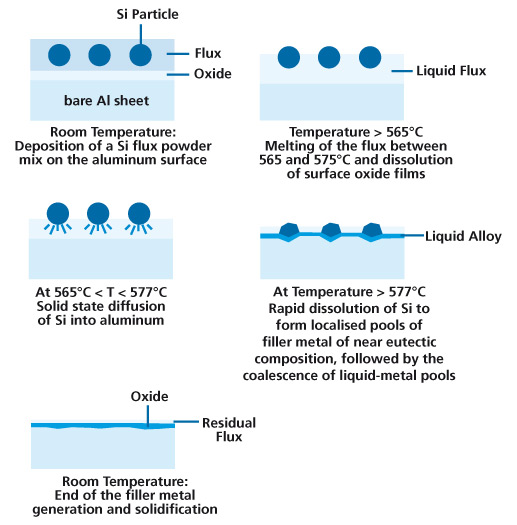

NOCOLOK® Sil Flux brazing is a technique, which eliminates the need for clad brazing sheet or conventional Al-Si filler metal. Sil flux brazing uses filler metal generated in-situ to effect brazing. The mechanism for creating this filler metal in-situ is described below:

- One of the surfaces to be joined is coated with a mixture of NOCOLOK® Flux and metallic Si powder. The coated assembly is then heated in the same fashion as in conventional furnace or flame brazing techniques.

- As the temperature rises, the flux melts at 565°C, dissolving the oxides on both the Al substrates and the Si particles.

- The bare Al surface is now in contact with metallic Si, and in the absence of oxides, allows solid-state inter-diffusion of Al and Si. Very quickly the composition near a Si particle reaches that of the Al-Si eutectic (Al-12.6% Si).

- As the temperature increases beyond the eutectic reaction temperature of 577°C, the formation of a liquid pool is established. The formation of the liquid leads to rapid dissolution of the remaining Si through liquid diffusion. The pool of liquid continues to grow, consuming Al, until all of the Si is consumed in the melt. In the presence of a joint, the liquid pool is drawn to the joint by capillary action.

- Upon cooling, the liquid layer solidifies to form a metallurgical bond between the components.

Sil Flux Process

we have two combinations of clad AA4343 for the tube / side bars and AA4045 for the tank and header for a one shot braze part. Fin is Unclad. We would like to know the temperature/ time profile compatibility between these two clads.

It is quite common to use different clad alloys on different components – i.e. as mentioned AA4343 on tube sheet and AA4045 on header plates. This is to adjust for the slight temperature differences that can be expected in the time temperature profile – with a little bit faster heat-up of thinner components (tubes) than thicker components (headers). This compensation provides gradual availability of the filler alloy for optimal process conditions at brazing temperature. The process profil is as usual – with surface temperature in the brazing zone of 600°C +/- 5°C – and holding time of 3 minutes +/- 0.5 minute at liquid filler alloy temperature (i.e. from 580°C heat-up to 605°C on cool-down).

Dear sir

Have a good day

We are looking to clad two Aluminum sheet alloy 1050 pure different sizes

To sticking together same hot rolling and cold rolling

We need your suitable materials like nocolok to sticking together

Pls advise us which matrial suitable to stick together to be very strong

And how can uses