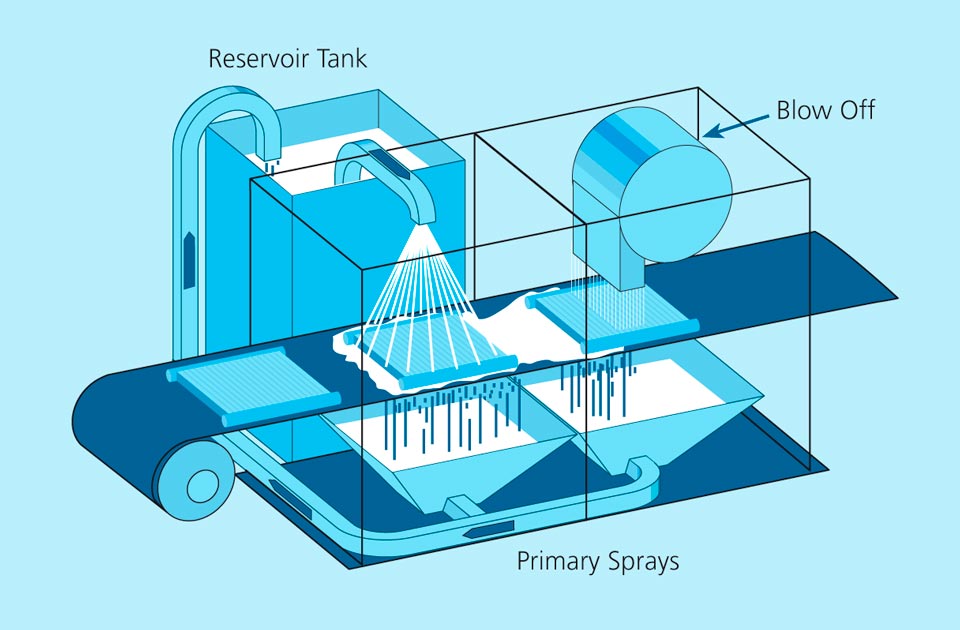

Flux Application: Wet Fluxing

In its simplest form, a slurry is held in a reservoir tank and continuously agitated to prevent settling. The slurry is pumped, usually with air-diaphragm pumps to the flux slurry cabinet where the heat exchangers moving on a conveyor are sprayed with the slurry. After spraying, the excess flux slurry is blown off in a separate chamber with high volume air. The over spray and blown off slurry is recycled back to the reservoir tanks, again using air-diaphragm pumps.

Depending on the sophistication desired, a second flux spray chamber may be installed after the first chamber to deliver a higher concentration slurry to problem areas such as tube to header joints in condensers and radiators. This second spray chamber would have a separate flux delivery system and a separate reservoir tank to contain the higher concentration flux slurry.

The components of the flux delivery system including reservoir and agitators should all be constructed of stainless steel or chemically resistant plastics (nozzles for instance). There should be no mild steel or copper containing components – includes brass or bronze – in contact with the flux slurry. The schematic below shows the components of a generic fluxing station:

Note that splashing will occur inside the fluxing cabinet and cause an accumulation of dried flux on the walls. Therefore the cabinet is washed with water periodically to remove this accumulated flux. The frequency of this maintenance operation is up to the manufacturer, but could be anywhere from once per shift to once per month.

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!