Summary

The article was written on the basis of frequently asked questions from companies which either wanted to start a new all-aluminium brazing production of heat exchangers or wanted to convert from copper and aluminium mechanical assembly design to all-aluminium brazed parts. The questions were grouped into three main categories: Equipment (emphasis on assembling process), Process (emphasis on different fluxes and fluxing methods) and Corrosion.

Specific production challenges are also presented, which are important not only to newcomers of all-aluminium brazed heat exchangers, but to established companies as well. These include typical brazing problems such as managing leaks and the basics of brazing copper to aluminium. These topics are discussed by their relevance to the brazing parameters and their role in successful brazing.

Content:

- Introduction (in this issue)

- Equipment (in this issue)

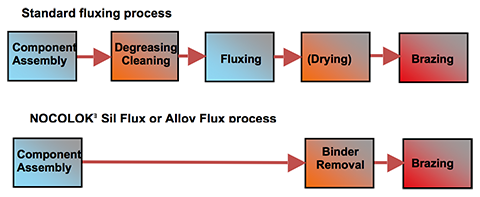

- Brazing process (in August issue)

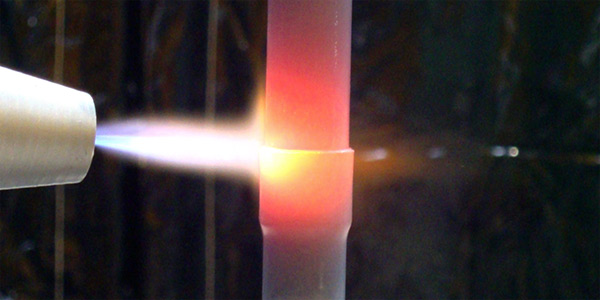

- Brazing copper to aluminium (in September issue)

- Corrosion resistance (in September issue)

- Summary (in September issue)

1. Introduction

Brazing Furnace

Increasing environmental concern has identified the air conditioning and refrigeration industry as one of the contributors to the greenhouse effect and ozone depletion.

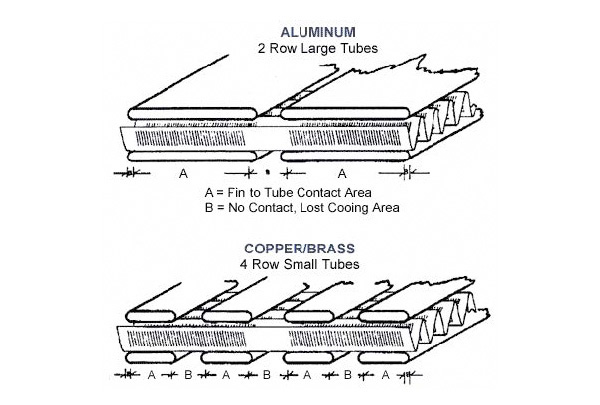

Accordingly to [1] 15% of all electricity consumption in the developed world is used by the air conditioning and refrigerator industry. Increasing the efficiency of these heat transfer systems has the positive impact of decreasing electricity consumption and therefore the overall emission of CO2. The advantages of all aluminium brazed condensers in an air conditioning system are well described in [2]. For example one such case study [3] allowed for saving about 2700 USD during 6 months. The above advantages are currently well recognized by both the air conditioning manufacturers and their end users. It is our observation that the majority of the companies in the HVAC industry which have started or are about to start production of aluminium brazed heat exchangers have only limited experience with aluminium brazing; therefore providing them with maximum possible technical assistance from the supplier side is of high importance.

This article was written on the basis of our contacts with such companies having an aim to offer some assistance to all newcomers and companies facing some troubles with their new type of production.

2. Equipment

In most cases, the first question from a company that wants to start a new aluminium brazing activity is: “What kind of furnace should I buy?”

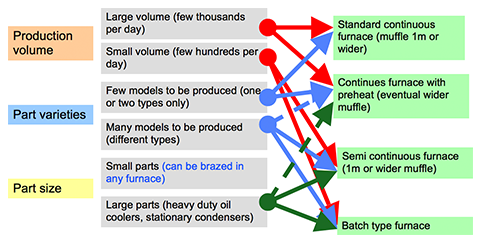

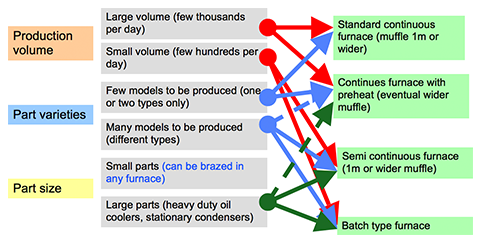

It is a complex issue which mainly depends on size of the products, its diversity and overall planned production volume. The general principles for the choice of the brazing furnace are shown in Fig. 1. It should be pointed out that the furnace manufacturers will make a brazing furnace customized to particular requirements of a given client.

Fig. 1: Basic principles for brazing furnace choice

Assembling units

In many cases the companies which are starting production of all aluminium brazed heat exchangers have been producing copper brazed heat exchangers. Therefore the natural question is: ”Can I use the same equipment which is used for copper units?”

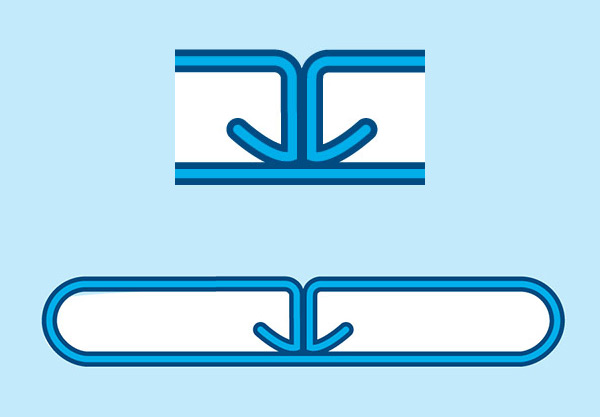

The straight forward answer is: No! Aluminium requires high precision for assembling (recommended gap size is 0.1 to 0.15mm), which is hardly ever achieved for brazing copper parts. Also one should remember that any copper contamination on aluminium can cause catastrophic brazing failures (holes).

The process of component assembly can be done on a simple manual stacker or on machines with varying degrees of automation through to fully automated units. The level of automation should be mainly determined by the planned production volume, but also other factors such as local labour costs should also be considered.

Basic requirements for a manual assembling unit:

- Cores must be assembled on a perfectly flat heavy steel plate

- After laying out the tubes and fins, the tubes must be pushed precisely into position determined by the slots in the headers.

- To secure the above requirement:

- movement of the pusher must be allowed only in one direction (no side or up movement),

- travel distance must be accurately controlled – e.g. by mechanical block on the pusher,

- it is useful to have a special distances between tubes to secure the right spacing for each header slot,

- the vertical alignment of the tubes must be secured either by steel plate or by hammering the tubes with a special pad.

- Threading the headers on the tubes should be done in one single action which does not allow for any side or vertical deflection of the headers.

- After threading the headers the fixtures should be assembled and the tube pusher released.

The process of the part assembly is invariably connected with fixtures; these are the steel elements which hold the parts together during brazing and then removed after brazing. The most frequently asked question is: ”What should be the design of the brazing frames/fixtures?”

Basically there are rigid and elastic designs which allow for some expansion when the core is heated. For larger cores elastic design is preferred. This type of fixture is reusable, also known as a permanent fixture and can go through the brazing cycle several hundred times. Apart from that we could use single usage fixtures, known as disposable fixtures and these include steel wire and steel bands. The multi-use fixtures must be made of stainless steel and in most cases the single use fixtures are usually made of ordinary low carbon steel.

Fig. 2: Example of rigid and elastic fixtures

When designing the length of the fixture (distance marked in red as Ls in fig. 2, one must remember thatthere is a difference in thermal expansion coefficient between aluminium and steel. To compensate for this, the following assumption is made: The length of the steel fixture at brazing temperature must be equal to the nominal width of the aluminium exchanger at brazing temperature. On this basis, an equation can be used describing the linear change of dimensions with temperature.

Ls(1 + αstΔt) = Lo(1 + αalΔt)

Where:

Ls – length of steel fixture,

αst – thermal expansion coefficient for the fixture material,

αal – thermal expansion coefficient for aluminium,

Δt – Increase of the part temperature during brazing,

Lo – Nominal width of the part.

As an example, for a part having width of 900 mm and nominal tube spacing of 8 mm, solving this equation and taking into account the fact that after assembly there must be some pressure exerted by the fixture on the part, the length of the fixture should be 907.5 mm and the fin height 8.08 mm. The longer steel fixture is compensated by the increased fin height. It also means that after assembly the part will have a slightly barrel-like shape (bowed out at the sides).

The question: ”What final checks are required for brazed parts?”is also connected to equipment purchases. All brazed parts must be checked for leak tightness. The most simple method is the so called “under water test”. In this case the part is pressurized with air and lowered into a water bath to look for bubbles. However some end users require more accurate and reliable methods. In the automotive industry it is common to check condensers for leaks with high pressure and extremely sensitive helium leak detection devices.

Each product should be accepted by the end user. In every case the scope of acceptance tests should be agreed to between the manufacturer and the end users. Typical tests include burst pressure, thermal cycling and of course standard ones for heat transfer efficiency and pressure drop. As a general rule it can be said that all aluminium parts should meet all the requirements applied to copper/brass parts.

References:

1. Hans W. Swidersky, “Brazed Aluminium Heat Ex-changers for the Refrigeration and Air Conditioning Industry”, APT Aluminium News, 1-2009

2. Bjørn Vestergaard, “Brazed Aluminium Heat Ex-changers – Ask for the inexpensive features”, Seminar “Aluminium Process-Technology for HVACR Industry” Vienna, March 21st-23rd, 2007

3. Case Study – Harris County Sheriff’s Building, “Carrier Turn to the Experts” 2006 Carrier Corporation 05/06 04-811-10206

Will be continued…