Flux Characteristics and Transfer Systems in Electrostatic Application – Part 4

Experiments for Flux Powder Fluidization:

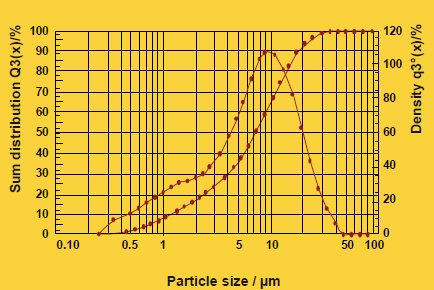

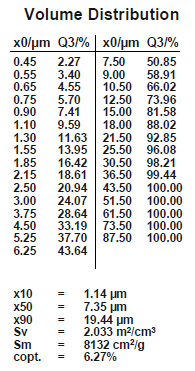

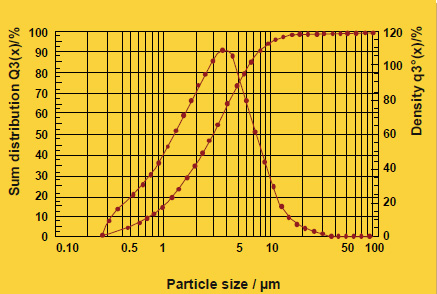

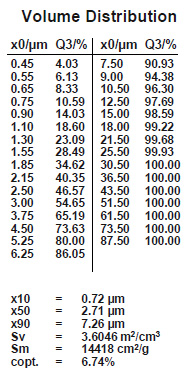

To illustrate the relationship between flux properties and fluidization, a series of tests was carried out using Sample 1 and Sample 2. Attached are print-outs of the particle size distribution analysis (Sympatec Helios H0851; dry powder analysis with laser) of both materials.

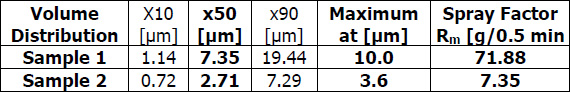

Table 1: Particle Size Distribution

Sample 1 shows coarser grain structure than sample 2. There are considerably more fine particles in sample 2, and most of that material has a size of below 5 μm. The spray factor of sample 1 (”coarse” material) is 71.88 g/0.5 min. This correlates with very good fluidization properties which was confirmed during tests in the electrostatic spray booth (see below).

Sample 1

For sample 2 (”fine” material), a spraying factor of 7.35 g/0.5 min was found. This reflects extremely poor fluidization properties, also confirmed by tests in the spray booth. The above indicates that there are at least three material characteristics connected to particle size affecting fluidization:

- Average particle size

- Quantity of fine particles

- Maximum particle size

Sample 2

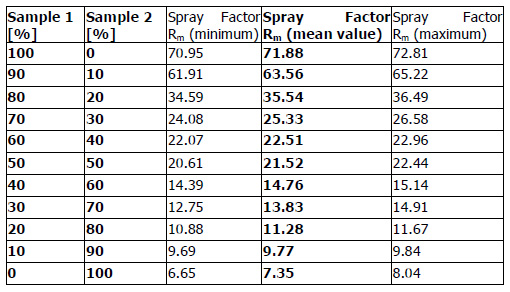

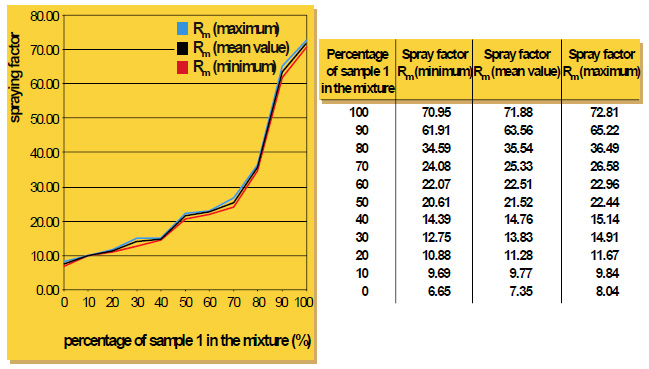

To further identify the effect of these factors, we tested mixtures of the two samples. In increments of 10%, sample 1 and sample 2 were blended. Then the spray factors of the mixtures were determined.

Table 2: Spray Factors in [g/0.5 min] of Sample Mixtures

As illustrated in the graph (see attachment), the relationship of spray factor and sample mixture ratio is not linear. Instead, it shows a rapid decline once the content of fine material is approximately 20 to 30%. We were able to specify the spray factor range of successfully performing flux powder to approximately 45 g/0.5 min in experiments with our dry fluxing booth, and from situations reported by our customers.

Spray Factor for Sample Mixtures

The ability of a powder to fluidize is very important for its performance in electrostatic application. However, it is not the only factor.

To be continued …

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!