Welcome to the aluminium brazing blog site. We will regularly be publishing articles about aluminium brazing in this blog and we look forward to your comments, remarks and questions. Behind the scenes in this blog are the specialists for aluminium brazing from Solvay Fluor. This blog is a corporate blog and offers you new, additional ways to communicate with us.

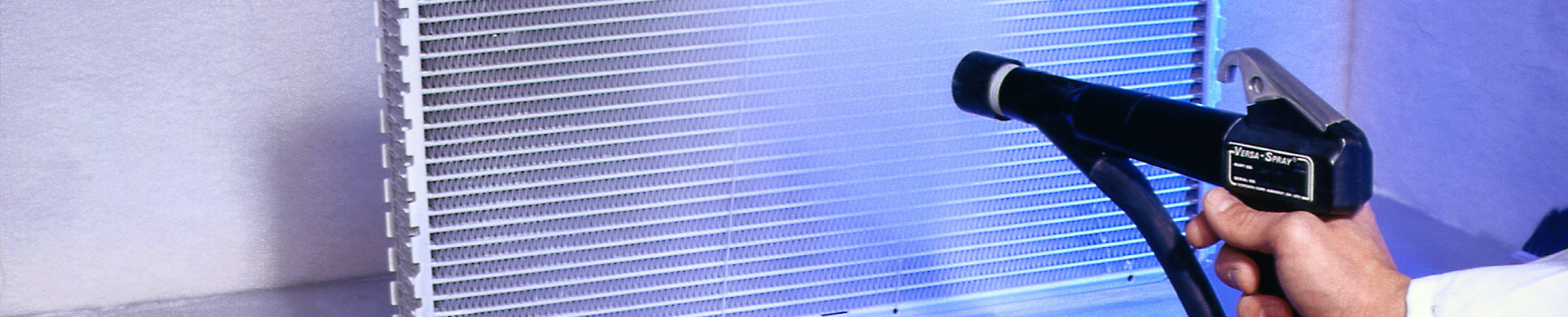

Flux Transfer Systems in Electrostatic NOCOLOK® Flux Application For these experiments, a fluxing booth from Nordson designed for semi-continuous production was used. This unit’s (216 cm height, 143 cm width, 270 cm depth) key components are a hopper, a spray gun, two filter cartridges and the necessary control units. The work piece is placed […]

Flux Powder Adhesion: Dust formation and flux fall off are of general interest to the brazing industry. Regardless of the application method, dust generation (particularly airborne fines) must be avoided or kept to a minimum. If dust formation cannot be prevented, local exhaust ventilation and meticulous housekeeping are recommended. The inhalation of flux dust […]

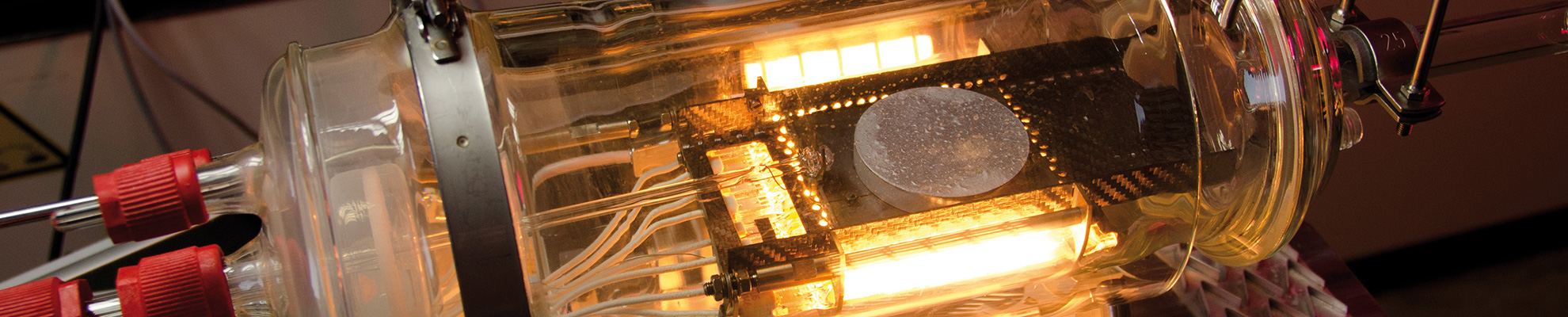

Experiments for Flux Powder Fluidization: To illustrate the relationship between flux properties and fluidization, a series of tests was carried out using Sample 1 and Sample 2. Attached are print-outs of the particle size distribution analysis (Sympatec Helios H0851; dry powder analysis with laser) of both materials. Table 1: Particle Size Distribution Sample 1 […]

Flux Powder Fluidization: In an effort to develop a flux with more desirable properties for electrostatic application, the first step is to qualify criteria. In summary of the above, it is apparent that fluidization is one of them. There is standard equipment available on the market to quantify fluidization characteristics. However, when we tested […]

The background of electrostatic flux application: When controlled atmosphere brazing with non-corrosive fluxes was introduced, the only realistic method for using the flux was wet application. This strategy was supported by the physical and chemical properties of flux powder. Non-corrosive fluxes for aluminum brazing consist of potassium fluoroaluminates (inorganic fluorides) with low water solubility. […]

Introduction: This article summarizes some experimental results of a project on electrostatic application of non-corrosive fluxes for aluminum brazing. The objective is to qualify and quantify flux powder properties and equipment parameters with positive effect for dry flux technology. For more than 30 years, controlled atmosphere brazing (CAB) [NOCOLOK ® Flux brazing] has been […]

Solvay is exhibiting on the Schweißen & Schneiden in Dusseldorf. Visit our stand in hall 13, booth number C16. The specialists from the NOCOLOK® Team will be on site – and are looking forward to meeting with you. The Schweißen & Schneiden (Welding & Cutting) is the international trade fair for joining, cutting, and surface treatment – taking […]

Brazing Issues Folded tubes (or B-type tubes) for radiators have been developed several years ago. There are slightly different designs patented by most of the heat exchanger manufacturers. Below illustrations show three different B tube designs: The folded tubes are produced from brazing sheet coils by a multi-step roll forming process – bringing the sheet […]